Ensuring optimal asset integrity

through specialized services, highly qualified personnel and the latest techniques and innovative solutions.

Independent service provider

National and international legislation

EN-ISO 9001:2015 & VCA*

Services

Proud to work for

Cases

Quality

EN-ISO 9001:2015 & VCA*Inspecto Visio is a consistent provider of products and services which meet all conditions required by clients as well by current applicable laws and regulations, as shows both in our day to day operations as well as in our ISO certification and VGM Checklist Aannnemers (VCA*).

Nice to meet you

Wolter van der ZeeOwner of Inspecto Visio, QA/QC Engineer/Manager and NDT level III Inspector. Hands-on professional.

Our highly qualified teams are usually brought in when people are at a loss. We always come up with a solution. In addition, we ensure quality control as well as provide substantial improvements, allowing our clients to work faster, smarter and better.

Projects we have worked on

Frequently Asked Questions

ABOUT OUR SERVICES

-

Does Inspecto Visio offer assistance services during the implementation of EN:1090/2?

Yes. We help design the procedures, allowing you to meet requirements regarding steelwork construction and subsequently submit a certificate application to a certifying agency.

-

Does Inspecto Visio also conduct damage assessments?

Yes, we certainly do. We investigate the cause of the damage, assess it as well specify how it can be repaired as soon and well as possible.

-

Does Inspecto Visio offer assistance during a Welding Procedure Quality Record (WPQR)?

Yes, we do. As soon as we are able to determine your precise welding plans, we offer assistance in compiling a WPQR. A Welding Procedure Specification (WPS) is – if requested – also an option, thus offering the welders in question the exact know-how for high-end welding which shall subsequently meet all requirements.

-

Does Inspecto Visio conduct Final Inspections?

Obviously. We conduct Final Inspections thus checking whether the end product meets your requirements. We also draw up Release Notes, which offer a conclusive assessment of a steel structure. In case requirements appear not to be met, we offer assistance in fixing all possible flaws or deficiencies, thus ultimately ensuring a high quality end product.

-

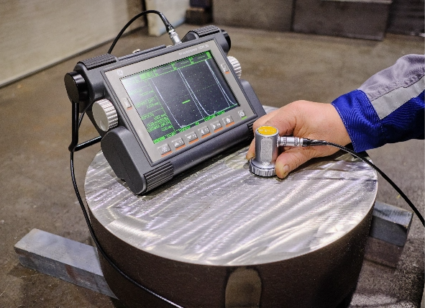

Does Inspecto Visio also conduct non-destructive testing (NDT)?

Yes we do. Or better: we outsource it to our specialised sister company NDO Nederland. NDO’s expertise is often called upon for specific assignments such as assessing the integrity of new welding joints or the quality of welding. This – to be more specific – includes Penetrant Testing (PT), Magnetic Testing (MT) as well as Magnetics Particle Inspection (MPI), Ultrasonic Testing (UT), Visual Testing (VT), Hardness Testing (HT), Positive Material Identification (PMI), Ultrasonic Bolt Testing (UTB), Roughness Testing (RT), Oxilyser Testing (OT) and XRF Analysis.